Learn the key warning signs that your tractor needs immediate spare part replacement. Avoid costly breakdowns and downtime with timely maintenance using quality parts from Gropart.

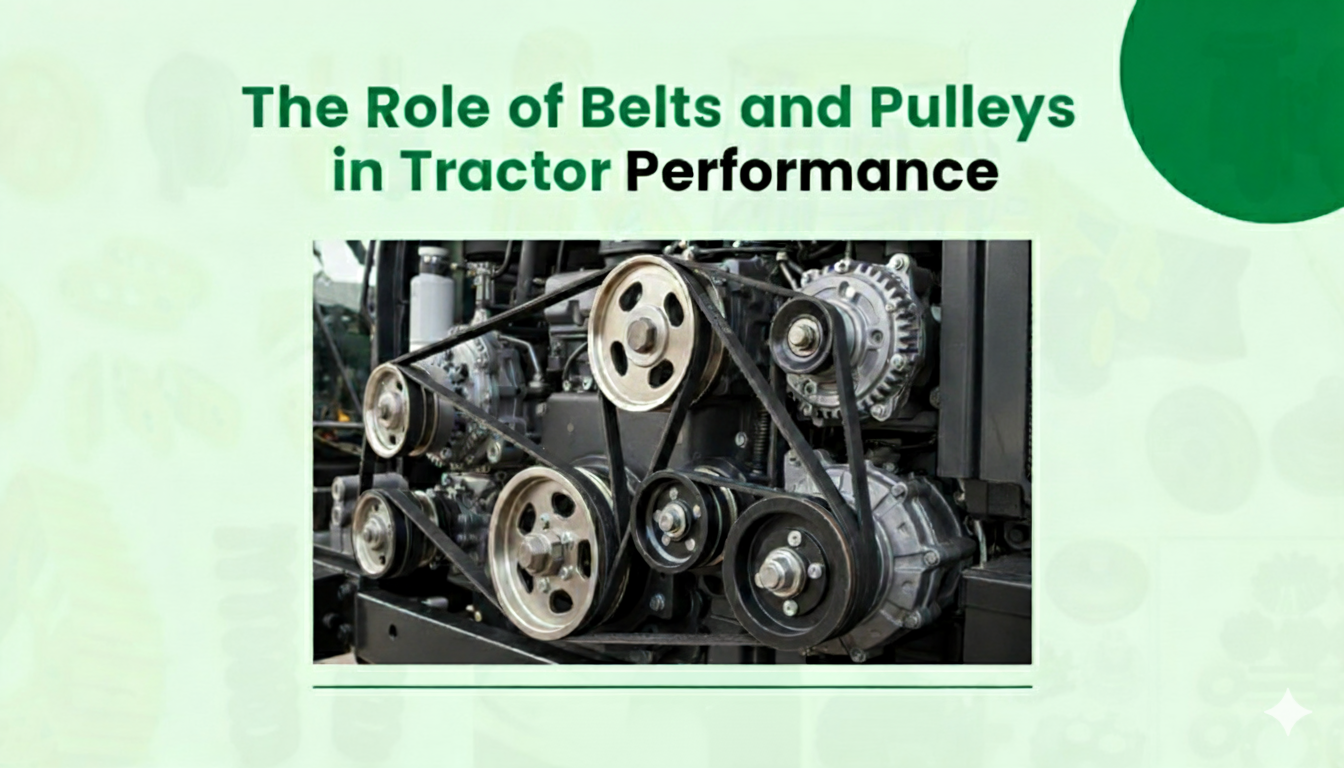

The Role of Belts and Pulley in Tractor Performance: A Complete Guide

Introduction

When it comes to tractor performance, most farmers think about the engine, tires, or hydraulics. However, there are other vital components that often go unnoticed but play a major role in ensuring smooth operations—belts and pulleys.

Belts are responsible for transferring power between different parts of the tractor, while pulleys help guide and regulate that power efficiently. From driving the alternator and water pump to ensuring proper functioning of the cooling system and other accessories, the belt and pulley system directly influences fuel efficiency, performance, and overall reliability of the tractor.

In this complete guide, we’ll explore the importance of belts and pulleys, how they work together, common issues farmers face, and why proper maintenance is crucial for keeping your tractor in peak condition.

What Are Belts and Pulley in Tractors?

In simple terms:

- Belts transfer power between different parts of the tractor.

- Pulleys act as wheels or guides that support the belts in transferring motion efficiently.

Together, the belt and pulley system ensures tractors run smoothly, driving essential functions like:

- Power transmission to the engine

- Operation of hydraulic systems

- Functioning of alternators and fans

- Smooth movement of cutting or harvesting equipment

Without them, tractors would lose efficiency and suffer frequent breakdowns.

How Belts and Pulley Improve Tractor Performance

1. Efficient Power Transmission

- Belts and pulleys deliver power from the engine to various components.

- They reduce friction, ensuring smoother energy transfer.

- Proper tension in the V-belt pulley for tractors prevents slippage.

2. Fuel Efficiency

- A well-maintained belt reduces unnecessary engine load.

- Farmers save fuel and cut operational costs.

3. Reduced Downtime

- Strong belts ensure uninterrupted farming activities.

- Less time wasted on frequent repairs or part replacements.

4. Extended Machine Life

- Using the best belts for agricultural machinery ensures your tractor’s engine and components stay safe from wear and tear.

Real-Life Farmer Example

Ramesh, a farmer from Rajasthan , shared his experience:

“During the harvesting season, my tractor belt broke, and I had to wait 3 days to get it replaced. Not only did I lose valuable time, but I also had to spend extra on emergency repairs. Later, I switched to genuine tractor belts and pulley from Gropart , and since then, I’ve had no breakdowns during peak season.”

Lesson: Investing in genuine, high-quality belts and pulleys saves farmers from unexpected downtime and losses.

Types of Belts and Pulley Used in Tractors

1. V-Belt Pulley for Tractors

- Most commonly used in tractors.

- Provides high power transmission efficiency.

- Reduces slippage due to its wedge shape.

2. Flat Belts

- Suitable for lighter power transmission.

- Less durable compared to V-belts.

3. Timing Belts

- Ensures synchronization of engine components.

- Critical for engine performance and fuel efficiency.

4. Double-Pulley Systems

- Used where multiple components need power at the same time.

- Increases operational flexibility.

Signs Your Tractor Belt or Pulley Needs Replacement

Farmers often miss early warning signs. Here’s what to look for:

- Cracks or fraying edges on the belt

- Squealing noise during operation

- Reduced tractor performance

- Excessive vibrations

- Pulley misalignment or visible wear

Tip: Inspect belts every 250–300 hours of tractor use to avoid breakdowns.

Genuine vs. Local Belts and Pulley: A Comparison

Feature | Genuine Tractor Belts & Pulley | Local/Duplicate Products |

Durability | Long-lasting, tested for farm conditions | Wear out quickly |

Fit & Compatibility | Designed specifically for tractors | Often requires adjustments |

Performance | Maintains smooth engine function | Reduces efficiency |

Fuel Economy | Saves fuel with proper tension | Wastes fuel due to slippage |

Cost (Long-Term) | Saves money with fewer replacements | Higher cost due to frequent breakdowns |

The choice is clear: genuine belts and pulleys protect your tractor investment.

Best Practices for Maintaining Tractor Belts and Pulley

- ✅ Regularly check belt tension and alignment

- ✅ Replace worn-out belts immediately

- ✅ Keep pulleys clean and free from dust buildup

- ✅ Avoid using duplicate spare parts

- ✅ Follow manufacturer’s service schedule

By following these steps, farmers can ensure maximum tractor efficiency and long service life.

Long-Term Benefits of Using Quality Tractor Belts and Pulley

- Consistent Performance: No unexpected breakdowns during peak farming.

- Lower Repair Costs: Genuine parts protect other tractor components.

- Higher Productivity: Keeps your tractor working at full efficiency.

- Better Resale Value: A well-maintained tractor fetches a higher price in resale markets.

Farmer Story – Why Quality Matters

Sohan from Madhya Pradesh learned the hard way:

“I once bought a cheap belt thinking I was saving money. But within 2 months, it snapped while plowing, damaging my alternator. The repair cost was three times more than the price of a genuine belt. Since then, I only trust branded tractor belts from Gropart .”

👉 Farmers across India prove that quality parts are always a smarter investment

Conclusion

Belts and pulleys may not be the largest components of a tractor, but their impact on performance is undeniable. A well-maintained belt and pulley system ensures smooth power transmission, reduces wear on the engine, and minimizes the risk of breakdowns during critical farming tasks. Regular inspections, timely replacements, and using quality spare parts are key to keeping your tractor efficient and reliable.

That’s why farmers across India trust Gropart for durable and high-performance tractor belts, pulleys, and other spare parts. With precision-engineered products built for long-lasting use, Gropart ensures your tractor delivers maximum power with minimum downtime.

FAQs on Tractor Belts and Pulley

1. How often should I replace tractor belts?

A.1 On average, every 250–300 hours of operation or sooner if signs of wear are visible.

2. Can I use any V-belt pulley for tractors?

A.2 No. Always choose a pulley that matches your tractor model specifications.

3. What are the best belts for agricultural machinery?

A.3 Belts made from high-strength rubber and fiber reinforcement are the most durable. Trusted suppliers like Gropart provide reliable options.

4. How can I prevent belt slippage?

A.4 Maintain proper belt tension, check pulley alignment, and avoid overloading the tractor.

5. Where can I buy genuine tractor belts and pulley online?

A.5 You can explore Gropart’s collection of Belts & Pulley for authentic, high-quality tractor parts.

English

English