Discover how genuine JCB backhoe spare parts improve machine speed, reduce downtime, and enhance operator safety. Buy reliable parts from Gropart for long-term performance.

Hydraulic Pump & Seal Problems in Tractors: Causes, Solutions & Maintenance Tips

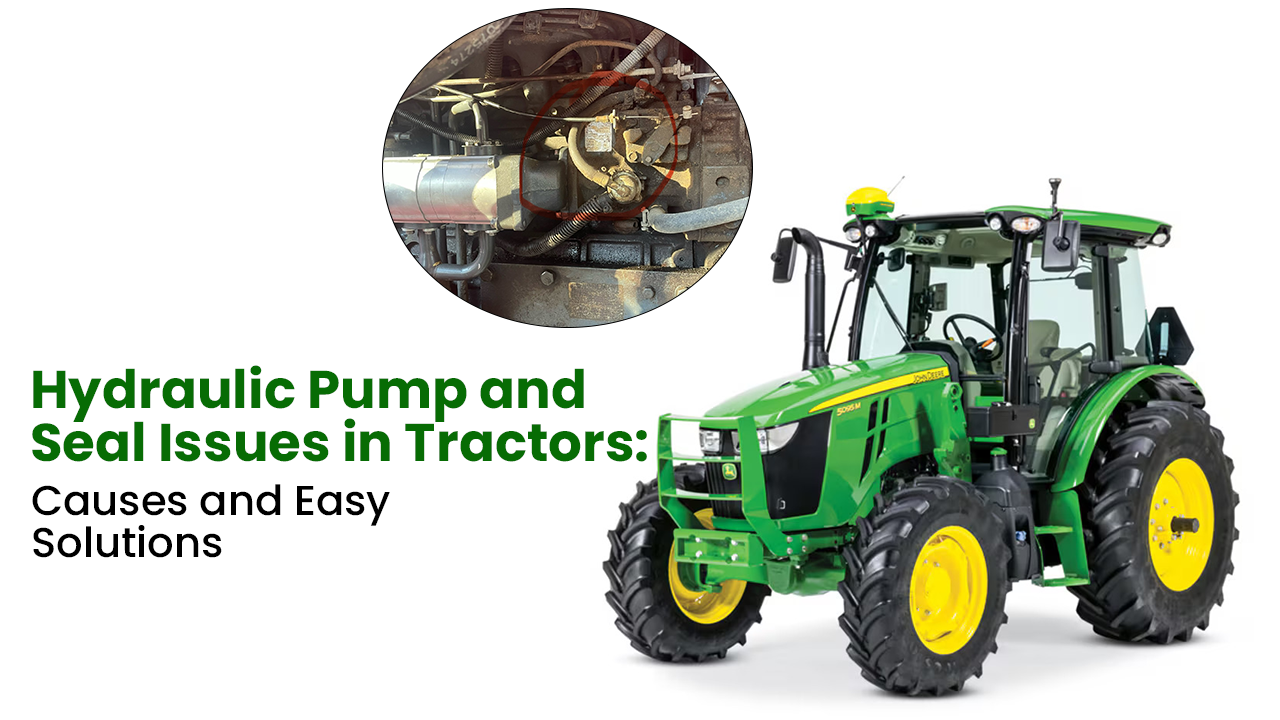

Hydraulic Pump and Seal Issues in Tractors: Causes and Easy Solutions

Hydraulics play a very important role in modern farming. From lifting ploughs and rotavators to operating trailers and loaders, most tractor attachments depend on a strong hydraulic system. At the center of this system are the hydraulic pump and hydraulic seals. When these parts do not work properly, farming work slows down and frustration increases.

Many tractor owners face problems like weak lifting, oil leakage, or jerky movement but are unsure about the real cause. In most cases, the issue comes down to worn pumps or damaged seals. Understanding these problems and knowing the right solutions helps avoid major breakdowns and expensive repairs.

How the Tractor Hydraulic System Works

A tractor hydraulic system converts engine power into lifting force. The hydraulic pump draws oil from the reservoir and pushes it through valves and pipes under pressure. This pressure moves the hydraulic cylinder, which lifts or lowers implements.

Hydraulic seals are used at different points to prevent oil leakage and maintain pressure. If either the pump or seals fail, the system cannot generate enough force.

Common Hydraulic Pump Problems in Tractors

1. Weak or No Lifting Power

One of the most common complaints is that the tractor cannot lift implements properly or lifts them very slowly.

Main causes include:

- Worn hydraulic pump

- Internal pump leakage

- Low-quality pump components

- Contaminated hydraulic oil

As the pump wears out, it cannot create the required pressure.

Easy solution:

Replace the worn pump with a reliable hydraulic pump from Gropart, designed for consistent pressure and long service life.

2. Jerky or Unstable Hydraulic Movement

If the implement moves up and down unevenly, it indicates unstable oil flow.

Possible reasons:

- Damaged pump vanes or gears

- Air entering the hydraulic system

- Low oil level

Easy solution:

Check oil level, remove air from the system, and inspect the pump. Using a quality hydraulic pump and correct oil prevents this issue.

3. Unusual Noise from Hydraulic Pump

Grinding or whining sounds from the hydraulic system are warning signs.

Common causes:

- Dry pump operation

- Contaminated oil

- Worn bearings inside the pump

Easy solution:

Change hydraulic oil, clean filters, and replace damaged pump parts with durable spares from Gropart.

Common Hydraulic Seal Issues in Tractors

Hydraulic seals may be small parts, but they play a big role in system performance. Even a small seal failure can lead to oil leakage and pressure loss.

1. Hydraulic Oil Leakage

Oil leaking around cylinders, pipes, or pump areas is a clear sign of seal failure.

Causes include:

- Worn or cracked seals

- Poor-quality seals

- Excessive pressure

- Heat and aging

Easy solution:

Replace old seals with high-quality hydraulic seals from Gropart, which are designed to handle pressure and temperature changes.

2. Slow Implement Response

When seals wear out, oil escapes internally, reducing pressure.

Common reasons:

- Internal seal leakage

- Incorrect seal size

- Improper installation

Easy solution:

Use properly sized and correctly installed seals to maintain pressure and fast response.

3. Frequent Seal Failure

If seals fail again and again, the root cause may not be the seal itself.

Possible reasons:

- Rough cylinder surfaces

- Contaminated oil

- Poor-quality replacement seals

Easy solution:

Inspect cylinder condition, clean the hydraulic system, and always choose reliable seal kits from Gropart.

Why Hydraulic Oil Quality Matters

Hydraulic oil plays a major role in pump and seal life. Poor-quality or contaminated oil increases wear and damages seals quickly.

Problems caused by bad oil:

- Pump wear

- Seal hardening

- Reduced pressure

- Overheating

Best practices:

- Use recommended hydraulic oil

- Change oil at regular intervals

- Replace hydraulic filters on time

Clean oil protects both the pump and seals, improving system life.

Importance of Proper Installation

Even high-quality hydraulic pumps and seals can fail if not installed correctly.

Common installation mistakes:

- Incorrect alignment

- Over-tightening seals

- Using the wrong seal size

- Dirty installation area

Always follow proper fitting procedures or consult an experienced mechanic to ensure correct installation.

Why Choose Quality Hydraulic Spare Parts

Cheap hydraulic spare parts may look attractive, but they usually fail quickly and damage other components.

Low-quality pumps and seals can cause:

- Repeat oil leakage

- Reduced lifting capacity

- Frequent breakdowns

- Higher repair costs

Gropart hydraulic pumps and seals are built for real farming conditions. They offer:

- Strong materials

- Accurate fitment

- Long-lasting performance

- Reduced maintenance needs

Simple Maintenance Tips to Avoid Hydraulic Problems

Regular care can prevent most hydraulic issues.

Helpful tips:

- Check oil level daily

- Clean hydraulic connections

- Replace worn seals early

- Avoid overloading implements

- Fix leaks immediately

Small maintenance steps save time and money in the long run.

Conclusion

Hydraulic pump and seal issues are among the most common tractor problems, but they are also the easiest to fix when identified early. Weak lifting, oil leakage, noise, and unstable movement are clear signs that the hydraulic system needs attention.

Using high-quality hydraulic pumps and seals from Gropart, along with proper oil and regular maintenance, ensures smooth operation and long-term reliability. For farmers who depend on hydraulics every day, investing in the right spare parts is not just a repair decision—it is a step toward efficient and trouble-free farming.

With the right parts, correct installation, and timely care, your tractor’s hydraulic system can continue to perform strongly for many years.

हिन्दी

हिन्दी